Air Tightness Testing

Air tightness testing is an essential part of modern construction as it is used to identify unwanted air leaks in the fabric of a building. With the increased levels of insulation required for compliance with current Building Regulations it has become even more important to ensure there is no heat loss via gaps around windows, doors and other areas in the building fabric. Testing must be done prior to plaster boarding to en-sure any air leaks are identified and fixed.

Current Building Regulations require that an Air Tightness Test be carried out on completion of any building project, the results of which form part of the energy assessment for the building.

As overseers of the Building Energy Rating (BER) scheme, SEAI require that individuals carrying out these tests demonstrate their competence by being certified under NSAI’s Air Tightness Testers Scheme or by being accredited by INAB or equivalent. It is no longer acceptable for the Air Tightness Testers to self certify that they follow the standards. If a building is tested by an unregistered person, the BER assessor cannot use the results to generate the BER and will have to use a default air permeability of 7m3/h/m2@50Pa in the DEAP calculations, where the building perhaps may obtain a result below 3m3/h/m2@50Pa. The use of the default figure will always result in failure of compliance with Part L.

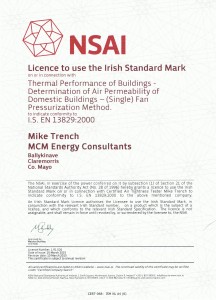

We are delighted to be the first company (at the time of writing) located in the Mayo/Galway region to be accredited by NSAI to carry out Air Tightness Tests (NSAI link) on both domestic and commercial buildings and provide test results which can be used in the DEAP calculation procedure for the production of a Building Energy Rating. Using a NSAI certified Air Tightness Tester will also ensure that the Assigned Certifier can submit all the required documentation for final sign-off of the building.

Enclosure Integrity Testing

Most modern office buildings now contain a server room within them which consists of an enclosure with a climate controlled environment for the optimum performance of the equipment contained within it. Also incorporated in these rooms is a clean agent fire suppression system which, in the event of a fire, automatically discharges a gas that extinguishes the fire.

In order for this system to be effective, the enclosure must be capable of holding the extinguishing agent for a minimum of ten minutes. Under I.S. EN 15004-1:2008, it is recommended that an enclosure integrity test be carried out to establish if this minimum retention time can be achieved. The test should be carried out on completion of the enclosure and then repeated annually and/or in the event of any works being carried out which may affect the integrity of the enclosure.

Peak Pressure

When a fire suppression system is discharged there is a short but dramatic increase in pressure within the enclosure. This is known as “Peak Pressure”. In order to ensure there is no structural damage caused by this increase in pressure it may be necessary to introduce a peak pressure venting system to alleviate this. As part of our integrity test we determine whether or not a venting system is required and will liaise with the design engineer with regard to the actual requirements for same.